Heating elements often fail too soon. You face downtime and costly replacements. Material choice directly solves this problem. Pick wrong, you lose money and time.

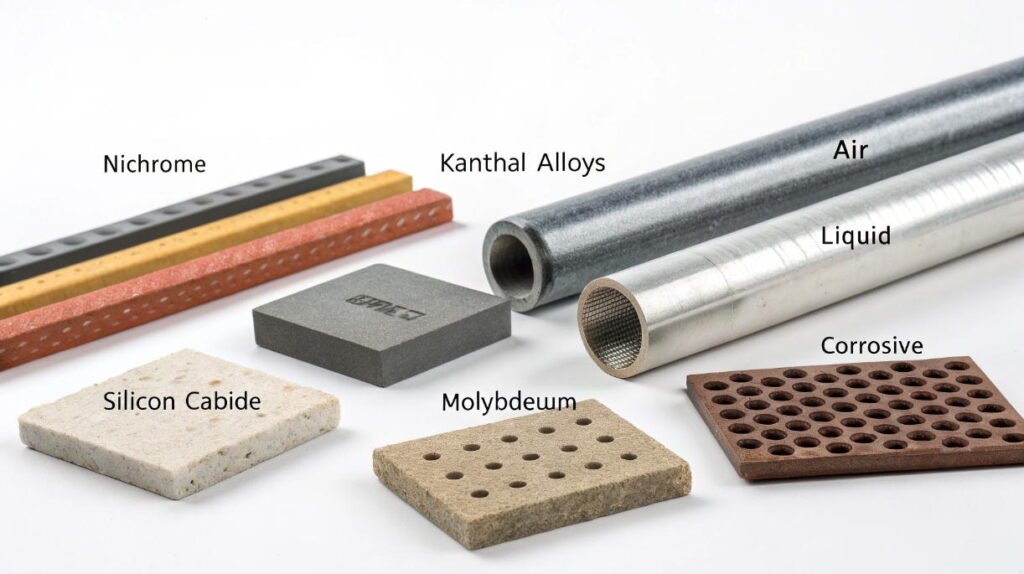

Material selection depends on application needs. Key factors include operating temperature, heating environment (air, liquid, corrosive), required lifespan, and cost constraints. Nichrome and Kanthal alloys work well for many common heaters. Silicon carbide or molybdenum suit extremes.

Choosing the right material is vital. You need the best performance for your specific use. It affects the heater’s life and your operating costs. Getting it wrong means frustration. Let’s look closer at your options.

Nichrome vs. Kanthal: Choosing the Best Heating Element Alloy for Your Application?

Your oven coil keeps burning out too fast? Material fatigue causes failures. Choosing between Nichrome (NiCr) and Kanthal (FeCrAl) fixes this.

For moderate temperatures below 1200°C in air, Nichrome 80/20 or Kanthal A-1 are top choices. Nichrome resists oxidation well and is easy to form. Kanthal withstands higher temperatures and develops a protective alumina layer. Consider cost and forming needs.

| Property | Nichrome (80/20) | Kanthal A-1 | Best For |

|---|---|---|---|

| Max Temp (Air) | Up to 1150°C (2100°F) | Up to 1400°C (2550°F) | Higher temp: Kanthal |

| Oxidation Resist. | Very Good | Excellent (Alumina Layer) | Long life air heating |

| Formability | Excellent (Softer) | Good (More Brittle) | Complex shapes: Nichrome |

| Cost | Generally Lower | Higher | Budget sensitivity: Nichrome |

Detailed Breakdown:

Nichrome 80/20 (80% Nickel, 20% Chromium) is excellent for many tasks. It’s reliable below 1200°C. This alloy is ductile. You can easily bend and form it into complex shapes. Think about oven coils or toaster wires. Nichrome has good oxidation resistance. This helps prevent rust. It often costs less than Kanthal. This matters for budget projects.

Kanthal A-1 (Iron-Chromium-Aluminium) wins with higher temperature tolerance. It handles up to 1400°C in air. The aluminium forms a tough, protective alumina scale on its surface. This layer shields the metal. It offers superior oxidation protection over time. This makes Kanthal ideal for long-life elements in hot air. Examples include industrial furnaces or high-wattage heating systems. It’s a bit stiffer than Nichrome. Form intricate shapes needs more care. It usually costs more. Decide based on temperature needs and lifespan goals. Both alloys work well overall.

High-Temperature Heating Elements: When to Use Molybdenum or Silicon Carbide?

Industrial furnaces failing over 1400°C? Standard alloys melt or break down. Your process gets interrupted, costing you money.

For extreme heat over 1400°C or inert/vacuum environments, alloys fail. Molybdenum resists creep up to 1800°C but oxidizes rapidly in air. Silicon Carbide excels above 1500°C in oxidizing atmospheres. Choose based on specific atmosphere and peak temperature.

| Characteristic | Molybdenum | Silicon Carbide (SiC) | Application Focus |

|---|---|---|---|

| Max Temp | Up to 1800°C (3270°F) | Up to 1620°C (2950°F) | Extreme heat: Moly |

| Atmosphere | Vacuum / Inert Only | Air/Oxidizing Atmosphere | Air use: SiC |

| Hot Strength | Excellent (Low Creep) | Good | Vacuum furnaces: Moly |

| Cold Strength | Brittle (Handle Carefully) | Very Brittle | Avoid impact: Both |

| Oxidation | Catastrophic Failure in Air | Forms Protective SiO2 Layer | Air furnaces: SiC |

When You Need Maximum Heat:

Standard alloys like Kanthal hit their limits near 1400°C. For hotter processes, other materials step up. Molybdenum handles extreme temperatures up to 1800°C. It keeps its strength well at these heights. But, molybdenum instantly reacts with oxygen. Use it only inside sealed systems. Applications include vacuum furnaces and inert gas atmospheres. Handle it carefully when cool; it breaks easily.

Silicon Carbide (SiC) tackles high heat right out in the air. It’s great for temperatures between 1500°C and 1600°C. Air won’t ruin it. SiC forms a protective silicon dioxide layer when hot. This layer shields the core material. You see SiC elements often in high-temperature ceramic kilns and industrial furnaces running in air. It lasts long under extreme conditions. It’s brittle like Molybdenum. Avoid bumps or thermal shock. Choose Moly for extreme inert/vacuum heat, SiC for blazing air furnaces.

5 Key Properties of Ideal Heating Element Materials (Melting Point, Resistivity & More)

Why do some heater materials fail unexpectedly? Ignoring core properties causes problems. Match properties to your specific heating job.

Critical properties are high melting point, sufficient resistivity, low temperature coefficient, good oxidation resistance, and high strength. Material must survive operating temperature without melting or deforming. Sufficient resistance heats efficiently without bulky elements.

| Key Property | Why It Matters | Example Material Value | Ideal Requirement |

|---|---|---|---|

| 1. Melting Point | Must be higher than operating temperature. | Kanthal: ~1500°C (2732°F) | >200°C above max temp needed |

| 2. Resistivity | Determines wire thickness and power for given heat. | Nichrome: ~1.10 µΩ·m | Optimized for heater design geometry |

| 3. Temp Coefficient | Electrical resistance shouldn’t change wildly with heat. | FeCrAl alloys: Low | Low α value preferred |

| 4. Oxidation Resistance | Prevents material breakdown in air at high temps. | Kanthal: Excellent (Alumina) | Forms stable, protective oxide layer |

| 5. Strength | Resists sagging or deformation at operating temp. | SiC: High hot strength | Avoids creep/sag |

Understanding Each Property:

Choosing the best material isn’t guesswork. Five main properties are critical for heater materials like tubes or cartridge heaters. High Melting Point: Your material must never melt in service. Kanthal melts around 1500°C – fine for a 1200°C furnace. Use SiC or Moly for hotter processes.

Sufficient Resistivity: This decides how thick the heating wire must be. Nichrome (1.10 µΩ·m) needs less cross-section than copper (0.017 µΩ·m) for the same heat. Find the right balance for your heater size.

Low Temperature Coefficient: You need predictable resistance as temperature changes. Kanthal resistance doesn’t increase much when hot. Poor resistivity control messes with power output.

Good Oxidation Resistance: Oxygen in the air attacks hot metal. Materials must shield themselves. Kanthal forms aluminium oxide; Silicon Carbide forms silicon oxide. This protective layer slows corrosion. It extends element life.

High Strength: Elements get soft when hot. They must resist stretching (creep) or sagging. Strong materials like molybdenum or dense SiC stay in position better. Weak materials can distort shorting out. Think about physical load.

Cost-Effective Heating Elements: Balancing Performance and Budget with Nichrome/Kanthal

Budget pressures forcing quick reorders? Cheaper heaters may fail sooner. Smart material choice balances upfront price and lifetime cost.

For many standard applications (below 1200°C), Nichrome often wins on raw material cost. Kanthal (FeCrAl) offers longer life in demanding conditions, saving replacement costs. Evaluate your specific temperature, environment, and required lifespan to find the true best value.

Balancing price and performance needs care. Don’t just pick the cheapest option initially. Consider the total life cost – upfront price plus replacements plus downtime. For many common tasks like kitchen appliances, domestic heaters, or moderate industrial ovens (under 1000°C), standard Nichrome 80/20 is usually very cost-effective. It works reliably. The wire itself often costs less than Kanthal per kilogram. It’s also easier to fabricate elements from it. This saves on manufacturing labor.

Kanthal alloys (like A-1, AF) have a higher initial cost. However, their performance justifies it in tougher jobs. They handle much higher temperatures – suitable up to 1400°C. Their superior oxidation resistance significantly extends service life. This is valuable in continuous process equipment like industrial ovens or heaters on expensive machinery. Fewer replacements mean lower downtime costs and less labour. Think long-term. If your heater must endure extreme heat cycles or corrosive atmospheres, Kanthal provides better lifetime value despite the higher sticker price. Sometimes paying more upfront means saving money overall.

Specialized Heating Elements Guide: From Oven Coils to Seat Heaters

Why does a one-size-fits-all heater fail? Demands differ wildly between applications. Specific environments demand tailored material solutions.

Different applications impose unique demands: vibration (cars), moisture (rice cookers), immersion (water heaters), aggressive media (salt furnaces), fast cycles (seat heaters). This dictates material choice beyond temperature. Nichrome and Kanthal cope with many household needs. Special cases require tailored alloys or non-metallics.

Material options grow as needs get specialized:

- Household Appliance Coils (Ovens, Toasters, Hair Dryers): Nichrome 80/20 dominates. Reliable, cost-effective, easy to form into tight coils.

- Water Immersion Heaters (Tubular Heater): Nickel-plated copper elements often shield the NiCr wire or MgO powder insulation from water, enhancing corrosion resistance.

- Defroster Grids (Cars): Copper-nickel or fine resistance wire offers durability against thermal shock and car vibrations.

- Fast Cycling Elements (Car Seat Heaters): Flexible Constantan or etched foil heaters handle repeated heating/cooling cycles without fatigue.

- Salt Bath or Lead Bath Furnaces: Pure nickel sheathed elements or specialized nickel-chrome alloys resist corrosion from aggressive molten media.

- Air Heaters requiring Ultra-Long Life: Upgrade to Kanthal APM or specially stabilized FeCrAl variants.

- Transparent Heaters: Indium Tin Oxide (ITO) deposited on glass provides see-through heating surfaces (defoggers).

Pick material based on the challenge.

Conclusion

Selecting the best heating element material means matching temperature, environment, lifespan, and cost needs. The right choice delivers lasting results and value.