Are you looking for the secret to making heating elements more efficient and reliable? The problem is you need to understand how important the materials are.

Yes, magnesium oxide (MgO) powder is very important for heating elements. It provides excellent thermal conductivity and electrical insulation. This keeps the heating element working effectively and safely.

Now that you know why MgO powder is important, let’s dive deeper into why it’s so important.

Why Magnesium Oxide Powder Is Essential for Heating Element Efficiency?

Do you ever wonder how a small heating element can produce so much heat safely? It all comes down to the materials used, especially magnesium oxide (MgO) powder.

Magnesium oxide (MgO) powder is important for heating element efficiency because it has great thermal conductivity. It can transfer heat quickly. And it also has very good electrical insulation to prevent short circuits.

What are the key benefits of using MgO powder in heating elements?

As someone who has been in the heating element industry for over 20 years since ELEKHEAT’s establishment in 1997, I’ve seen firsthand how MgO powder can improve heating element performance. Let me break down the key benefits for you:

| Benefit | Description |

|---|---|

| Thermal Conductivity | MgO powder helps transfer heat away from the resistance wire quickly and evenly. This prevents the wire from overheating and failing. The better the thermal conductivity, the more efficient the heating element. |

| Electrical Insulation | MgO powder is a great electrical insulator. It stops the current from short-circuiting to the metal sheath of the heating element. This is very important for safety and keeps the element working as it should. |

| High-Temperature Stability | MgO can handle high temperatures without breaking down. This is important because heating elements often get very hot. It ensures that the heating element lasts longer and works well even when it’s very hot. |

| Chemical Inertness | MgO doesn’t react easily with other materials. This means it won’t corrode or contaminate the resistance wire or the sheath. This keeps the heating element clean and working well over time. |

| Compactibility | MgO powder can be packed tightly around the resistance wire. This makes sure there are no air gaps that could reduce heat transfer. A tightly packed MgO powder ensures good contact and efficient heating. From my experience, the density of the filling is also very important. |

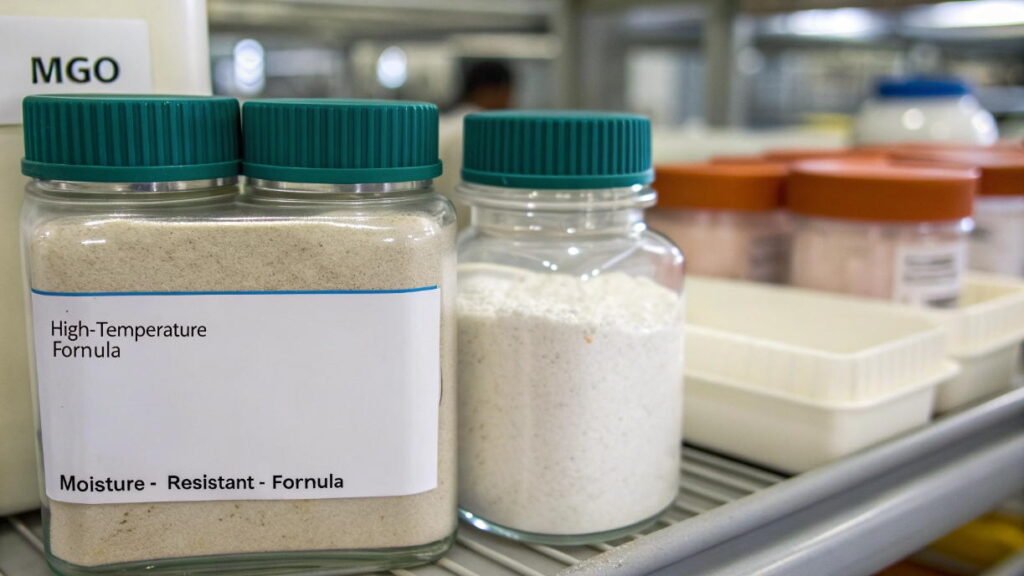

Choosing the Right MgO Powder: High-Temp vs. Moisture-Resistant Formulas?

Choosing the right magnesium oxide (MgO) powder is like choosing the right tool for a job. The right choice makes all the difference.

When choosing MgO powder, consider whether you need a high-temperature or moisture-resistant formula. High-temperature formulas are for elements that get very hot, while moisture-resistant formulas are for humid environments. Pick the one that fits your needs.

How do you select the best MgO powder for specific applications?

Selecting the right MgO powder is important for the performance and life of heating elements. I remember one time we used the wrong type of MgO powder for a high-temperature application. The heating element failed quickly, and we had to replace the whole batch. Here’s a guide to help you make the right choice:

| Feature | High-Temperature MgO Powder | Moisture-Resistant MgO Powder |

|---|---|---|

| Temperature Range | Designed for applications where heating elements operate at very high temperatures (e.g., above 800°C). It maintains its thermal and electrical properties even under extreme heat. | Formulated to resist moisture absorption. It prevents the MgO powder from clumping or losing its insulation properties in humid environments. |

| Purity Level | High purity is important to avoid impurities that can affect performance at high temperatures. Look for MgO powder with a purity level of 98% or higher. | Special additives are often included to repel moisture. These additives do not affect the thermal and electrical properties of the MgO powder. |

| Grain Size | Finer grain sizes can provide better compaction around the heating element wire. This ensures good thermal contact and efficient heat transfer. | Larger grain sizes may be preferred to allow for better ventilation and prevent moisture from being trapped. |

| Applications | Ideal for high-temperature furnaces, ovens, and kilns. Also used in heating elements for industrial processes that require extreme heat. | Best for applications in humid or wet environments, such as water heaters, coffee machines, and some types of industrial heating. |

| Considerations | Make sure the MgO powder can withstand the maximum operating temperature of your heating element. Also, check the thermal conductivity to make sure it meets your heat transfer requirements. | Check the moisture resistance rating to make sure it’s suitable for the humidity levels in your application. Also, consider any specific requirements for food-grade or medical-grade applications. |

The Science Behind MgO’s Thermal Conductivity and Electrical Insulation

Have you ever wondered why magnesium oxide (MgO) is so good at both conducting heat and insulating electricity? It seems like a contradiction, right?

Magnesium oxide (MgO) can conduct heat well because of its crystal structure. This structure allows heat energy to pass through easily. At the same time, it is a good electrical insulator because it doesn’t have free electrons that can carry electrical current.

How does MgO achieve this unique combination of properties?

The secret to MgO’s special properties lies in its atomic structure and how it behaves at a microscopic level. As someone who has spent years working with this material, let me explain how it works:

| Property | Explanation |

|---|---|

| Thermal Conductivity | MgO has a crystal structure similar to that of sodium chloride (table salt). This structure allows phonons (vibrational energy) to travel through the material easily. Phonons are the main way heat is transferred in solids. The more easily phonons can move, the better the material conducts heat. MgO’s crystal structure is very efficient at allowing phonon movement, making it an excellent thermal conductor. |

| Electrical Insulation | MgO is an electrical insulator because its electrons are tightly bound to the magnesium and oxygen atoms. There are very few free electrons that can move around and carry an electrical current. This is different from metals, which have many free electrons. The lack of free electrons in MgO means that it resists the flow of electricity, making it a very good electrical insulator. |

| Crystal Structure | The crystal structure of MgO is very stable, which means it can withstand high temperatures without breaking down or losing its properties. This stability is due to the strong ionic bonds between the magnesium and oxygen atoms. These bonds hold the crystal structure together even at high temperatures, making MgO a reliable material for heating elements. |

| Purity | The purity of MgO powder is important for both its thermal and electrical properties. Impurities can disrupt the crystal structure and create pathways for electrical current to flow. This can reduce the thermal conductivity and electrical insulation of the MgO powder. That’s why high-quality MgO powder is very pure, with very few impurities. |

Industrial Applications: How MgO Powers Heating Elements from Ovens to Thermocouples

Have you ever stopped to think about all the places you can find heating elements? They’re everywhere, from your kitchen oven to complex industrial machinery.

MgO powder is used in heating elements in ovens, water heaters, and industrial equipment. It helps them heat up quickly and safely. It also extends the life of these elements by protecting them from electrical shorts and overheating.

Where exactly are MgO-based heating elements used, and why?

MgO-based heating elements are used in many different industries because of their reliability and efficiency. As someone who has worked with many clients across various sectors, I can share some specific examples:

| Industry | Application | Why MgO is Important |

|---|---|---|

| Home Appliances | Ovens, water heaters, coffee machines, and electric kettles. | MgO provides the necessary insulation and heat transfer to ensure these appliances heat up quickly and safely. It also helps to prevent electrical shocks and extends the life of the heating elements. |

| Industrial Equipment | Plastic injection molding machines, die casting equipment, and industrial ovens. | MgO ensures precise temperature control and uniform heating. This is important for making sure that the products are high quality and that the processes are efficient. The high-temperature stability of MgO is also crucial for these demanding applications. |

| Automotive | Heating systems for car seats and defrosting systems. | MgO provides reliable and efficient heating in cold conditions. Its insulation properties ensure that the heating elements are safe to use in the confined space of a vehicle. |

| Food Processing | Commercial ovens, fryers, and heating elements for food packaging. | MgO helps to maintain consistent temperatures for cooking and packaging. This is important for food safety and quality. The chemical inertness of MgO ensures that it does not contaminate the food products. |

| Laboratory and Medical | Laboratory ovens, autoclaves, and heating elements for medical devices. | MgO provides precise temperature control and reliable performance. This is important for accurate and consistent results. The high-purity of MgO ensures that it does not interfere with sensitive experiments or medical procedures. |

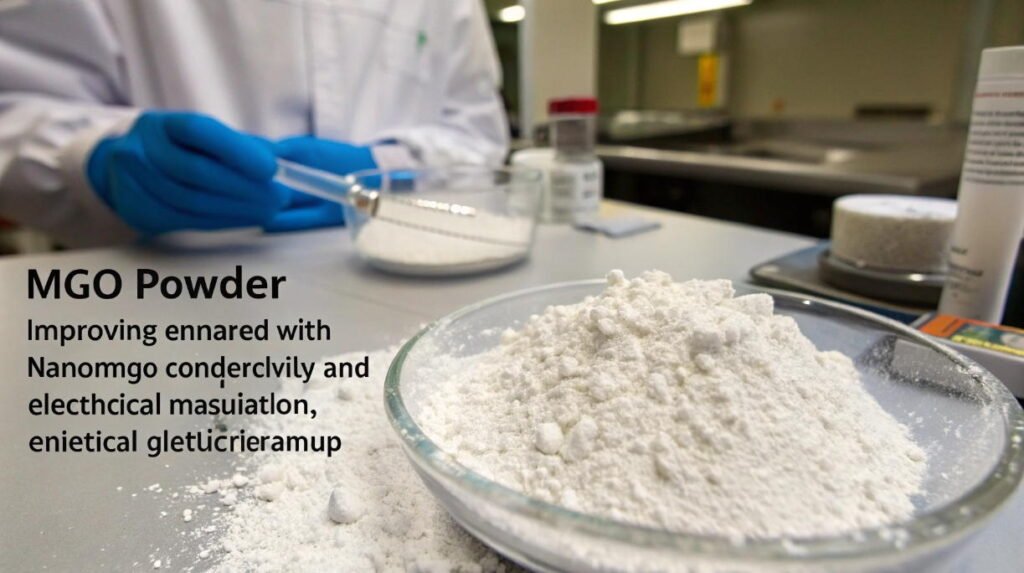

Future Trends: Innovations in MgO Powder for Next-Gen Heating Elements

What does the future hold for magnesium oxide (MgO) powder in heating elements? The possibilities are very interesting as technology keeps advancing.

In the future, MgO powder may be made with nanomaterials to improve its thermal conductivity and electrical insulation. Self-healing MgO composites that can repair damage are also being developed. These innovations will create more efficient and longer-lasting heating elements.

What cutting-edge developments can we expect in MgO powder technology?

The future of MgO powder is all about improving performance, durability, and sustainability. As someone who is always looking for new ways to improve our products, I am excited about these innovations:

| Trend | Description |

|---|---|

| Nanomaterials | Researchers are exploring the use of MgO nanoparticles to improve thermal conductivity and electrical insulation. Nanoparticles have a larger surface area, which can enhance heat transfer and reduce electrical leakage. Nanomaterials can also make the MgO powder more compact and uniform, improving its overall performance. |

| Self-Healing Composites | Self-healing MgO composites are designed to repair damage automatically. These materials contain special additives that are released when the MgO powder cracks or degrades. These additives fill the cracks and restore the thermal and electrical properties of the material. This can significantly extend the life of heating elements and reduce maintenance costs. |

| 3D Printing | 3D printing technology is being used to create complex shapes and structures with MgO powder. This allows for the design of heating elements with customized heating profiles and improved efficiency. 3D printing can also reduce material waste and manufacturing costs. I think it will also be a trend for heater manufacturing. |

| Sustainable Sourcing | There is a growing focus on sourcing MgO powder from sustainable and environmentally friendly sources. This includes using recycled materials and reducing the energy consumption during the manufacturing process. Sustainable MgO powder is not only better for the environment but can also improve the reputation of companies that use it. |

Conclusion

MgO powder is very important for heating elements. It ensures they are efficient, safe, and long-lasting. As technology advances, MgO will continue to play a key role in heating solutions.