Confused by similar names like "light-burned" and "light" magnesia? Choosing the wrong one can hurt your product quality and budget. Let’s clear up the confusion for good.

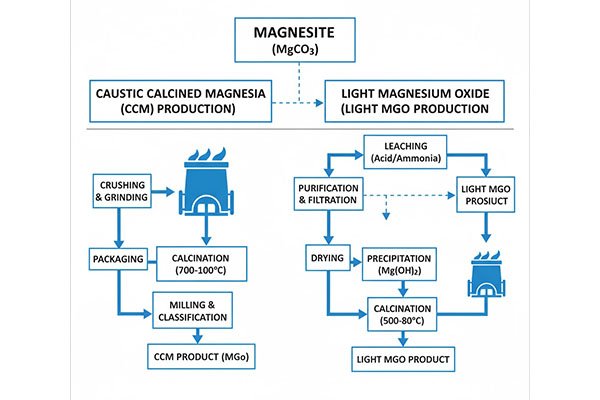

Light-burned magnesia (CCM) is defined by its production process—calcining magnesite at 700–1000℃. Light magnesium oxide is defined by its physical form—a low-density, high-purity powder made chemically. CCM is for bulk industrial use, while light MgO suits high-end applications.

The names sound almost the same, and customers often ask me to clarify the difference. In my 15 years as a sales manager at Chimag, I’ve seen firsthand how picking the right one makes a huge difference in performance and cost. Let’s break down where the confusion starts and what you really need to know to make the right choice for your application. It’s simpler than you think.

How do their definitions really set them apart?

Do technical terms like "light-burned" and "light" magnesia seem interchangeable? This common misunderstanding can lead to major production issues. Here’s the fundamental difference you need to understand.

Light-burned magnesia, or Caustic Calcined Magnesia (CCM), gets its name from its production process: a "light" or low-temperature calcination. Light magnesium oxide, however, is named for its physical property: its very low, or "light," bulk density.

I remember a client in the rubber industry who was using CCM and struggling with inconsistent curing times. They thought "light" just meant a finer powder. When we switched them to true light magnesium oxide, its high reactivity and purity stabilized their process immediately. This experience highlights a key distinction.

The Process-Defined Product: CCM

Light-burned magnesia is truly a product of its process. We take natural magnesite ore and heat it in a kiln at temperatures between 700°C and 1000°C. This specific temperature range drives off most of the carbon dioxide but leaves the resulting magnesium oxide (MgO) in a highly reactive or "caustic" state. Its name is tied directly to this manufacturing step. It’s a robust, cost-effective material designed for large-scale industrial jobs where high reactivity is needed, but extreme purity isn’t the top priority.

The Property-Defined Product: Light MgO

Light magnesium oxide is all about its physical characteristics. Its name describes its most obvious feature: it’s a very fluffy, low-density powder. This is because it’s made through a completely different route, usually a chemical precipitation method. This process creates extremely fine particles with a huge surface area, making it incredibly reactive and pure. It’s not just a material; it’s a specialty chemical engineered for performance.

What makes their production processes so different?

Wondering why two types of magnesia have such different costs and properties? The secret lies deep within their unique production methods. Let’s look at exactly how they are made.

Light-burned magnesia comes from heating natural rock (magnesite) in a kiln. Light magnesium oxide is created through a controlled chemical reaction, usually starting with seawater or brine. This fundamental difference in origin creates two vastly different materials from the start.

The best way I can show you the difference is to walk you through the two paths we take at our Chimag facility. It’s like comparing a stone mason carving a block of granite to a pharmacist compounding a precise formula. Both are skilled processes, but the tools, raw materials, and end goals are worlds apart. One creates a powerful workhorse, and the other creates a refined specialist. Let’s dig into the details to see why.

Here is a direct comparison of the two production routes:

| Feature | Light-Burned Magnesia (CCM) | Light Magnesium Oxide (Light MgO) |

|---|---|---|

| Raw Materials | Magnesite, Dolomite | Seawater, Bittern, Magnesium Hydroxide |

| Calcination Temperature | 700–1000℃ | 800–1100℃ |

| Main Equipment | Vertical Kiln, Rotary Kiln | Precipitation Reactor, Drying Furnace |

| Crystal Structure | Microcrystalline or Fine-grained | Amorphous or Extremely Fine-grained |

| Reactivity | High | Extremely High |

| Density | 1.0–1.5 g/cm³ | 0.2–0.5 g/cm³ |

| Specific Surface Area | 10–50 m²/g | 50–200 m²/g |

The process for CCM is straightforward and powerful. We mine magnesite, crush it, and feed it into a large rotary kiln. It’s a continuous, high-volume process designed for efficiency, making CCM a cost-effective choice for industries like agriculture and steel.

In contrast, making light magnesium oxide is a multi-step chemical process. We start with a magnesium-rich liquid, precipitate magnesium hydroxide, and then carefully wash, dry, and calcine it. Each step is controlled to ensure high purity and specific particle properties. This precision is why it’s the go-to for pharmaceuticals and specialty rubber.

Where do their applications diverge the most?

Your project needs magnesium oxide, but which one is the right fit? Using the wrong type can be a costly mistake. Let’s explore where each product truly shines.

Light-burned magnesia is the workhorse for heavy industries like refractory materials, agriculture, and environmental water treatment. Light magnesium oxide is the specialist, excelling in high-value applications like pharmaceuticals, food additives, and high-performance rubber.

I once worked with a customer developing a new type of animal feed supplement. They initially chose light magnesium oxide for its high purity. However, the cost was too high for their market. We switched them to a specific grade of our light-burned magnesia that met the nutritional and safety requirements but at a fraction of the cost. Their product became a success. This shows that the "best" material is always the one that best fits the application’s specific technical and commercial needs.

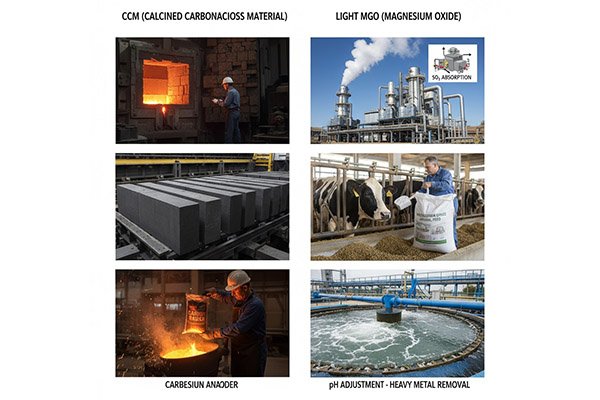

Common Uses for Light-Burned Magnesia (CCM)

Because it’s produced in large volumes and is highly reactive, CCM is perfect for jobs that need a lot of material without breaking the bank.

- Agriculture: It’s widely used to make magnesium fertilizer and neutralize acidic soil.

- Refractory Materials: It’s a key ingredient in cements and monolithic refractories used in steelmaking.

- Environmental Treatment: It’s great for neutralizing acidic wastewater and removing heavy metals.

- Chemicals and Rubber: It acts as a filler, acid scavenger, and vulcanizing agent in many industrial processes.

High-Value Applications for Light Magnesium Oxide

The extremely high purity, low density, and high surface area of light MgO make it essential for sensitive and high-performance applications.

- Pharmaceuticals and Food: It is used as an antacid, a magnesium supplement, and as a food additive (E530) due to its purity.

- High-Performance Rubber: It serves as a superior activator and stabilizer in specialty rubbers like neoprene, where performance is critical.

- Chemicals: It acts as a catalyst or catalyst support in fine chemical synthesis where reactivity and purity are paramount.

- High-End Agriculture: Its properties are ideal for premium foliar fertilizers that require rapid absorption by plants.

What is the final verdict for your specific scenario?

Choosing between these two materials still feels complex? You want to make the most cost-effective decision without compromising quality. Here are the clear guidelines to help you choose wisely.

Choose light-burned magnesia (CCM) when your primary goals are cost control, high volume, and industrial-scale reactivity. Select light magnesium oxide when you require superior purity, extremely high reactivity, low impurities, and specific physical properties like whiteness.

My guiding principle for customers has always been: start with your application’s non-negotiable requirements. I ask them, "What is the one thing this material must do?" Is it neutralizing acid on a massive scale? Or is it being pure enough to be used in a medical device? Answering that one question almost always points directly to the right type of magnesium oxide. Your final choice should be a balance of performance, purity, and price.

Here’s a quick reference guide I use to help my clients decide:

- For Cost-Effectiveness in Bulk Applications: If you work in building materials, steel smelting, or environmental desulfurization, light-burned magnesia (CCM) offers the best performance for the price. Its industrial-grade strength is perfect for these demanding jobs.

- For High Purity and Precision: If your industry is pharmaceuticals, cosmetics, high-performance polymers, or electronic materials, light magnesium oxide is your only choice. Its low impurity profile and high reactivity ensure product safety and superior performance.

- When Reactivity is Key: For chemical processes where reaction speed and efficiency are critical, the extremely high surface area of light magnesium oxide makes it the clear winner.

- Ease of Handling and Formulation: The "light" and fluffy nature of light MgO can be a benefit in certain formulations, allowing for better dispersion and a smoother final product.

Why trust Chimag for your magnesia needs?

Looking for a reliable supplier who understands these differences? You need a partner, not just a vendor, to ensure you get the right product every time. Let me explain our advantages.

At Chimag, we are not just manufacturers; we are specialists with 30 years of experience in both light-burned and light magnesium oxide. We offer tailored solutions with strict quality control, ensuring you receive the ideal product for your specific application.

After 15 years here, I can confidently say that our strength lies in our deep understanding of our customers’ processes. We don’t just sell MgO; we provide solutions. We have invested heavily in R&D and quality control to master the production of both types of magnesia. This allows us to guide you to the perfect grade, whether you need a cost-effective workhorse or a high-purity specialist. Our goal is to make your products better and your production more efficient.

Our Commitment to Quality and Customization

We have built our reputation on providing stable, high-quality products. Here’s what sets Chimag apart:

- Diverse Product Lines: We produce a wide series of MgO products with different activity levels and purities. This means we can meet the unique needs of clients in the building materials, rubber, environmental protection, agriculture, and pharmaceutical industries.

- Strict Impurity Control: We maintain rigorous control over impurities like Fe₂O₃, CaO, and SiO₂. This is crucial for applications where even trace amounts of contaminants can cause major problems.

- Proven Global Performance: Our products are exported to markets in Europe, South America, and the Middle East. Customers in these demanding markets consistently praise our products for their stability and excellent dispersibility in their systems.

- Expert Support: My team and I are here to be your partners. We use our extensive experience to help you select the most effective and economical solution, ensuring you never have to second-guess your choice.

Conclusion

Light-burned magnesia is your industrial workhorse for bulk applications, while light magnesium oxide is your high-purity specialist for refined uses. Choosing correctly ensures both performance and cost-effectiveness.